Qingdao Exceed Fine Chemicals Co., Ltd is a high-tech enterprise that integrates manufacturing and

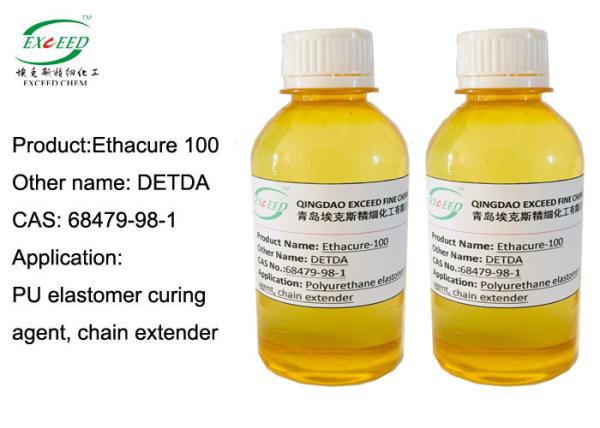

trading. We specialize in the production of polyurethane-based

products.

Our company is dedicated to investing in research and development

of cutting-edge products, collaborating with leading Chinese

universities and institutions. We have successfully developed a

heat-vulcanization, environmentally friendly bonding adhesive that

rivals the quality of world-renowned brands like Lord and Dow.

At Exceed, we believe in the power of science

Qingdao Exceed Fine Chemicals boasts a team of over 30 skilled technicians, supported by

advanced manufacturing equipment and robust production processes.

We maintain an independent R&D institute and foster strong

collaborations with leading universities and research institutions

to continuously enhance our production processes, product quality,

and performance.

With decades of dedicated efforts, we have successfully exported

our products to markets across the globe, including Europe, Asia,

North America, South America, Oceania, and Africa.

Furthermore, leveraging our extensive domestic network, we act as a

reliable purchasing agent, assisting customers in sourcing specific

materials according to their unique requirements.

Furthermore, we employ a dedicated team of quality control

(QC) professionals with expertise in the field of chemicals. This

rigorous quality control ensures consistent and reliable product

quality for our valued customers.

Currently, we achieve annual export sales exceeding USD 30 million

to over 30 countries worldwide, encompassing a diverse product

range including polyurethane chemicals, heat-vulcanization

environmental friendly bonding adhesive etc.

We understand that customers prioritize competitive pricing,

exceptional quality, and consistent product availability. We firmly

believe that Exceedchem is the ideal partner to fulfill your

specific needs.

As a trusted purchasing agent for clients worldwide, we leverage

our extensive experience to source high-quality products at

competitive prices. Our primary objective is to deliver the most

cost-effective solutions while maintaining the highest standards of

quality.